Home

Home

Back

Back

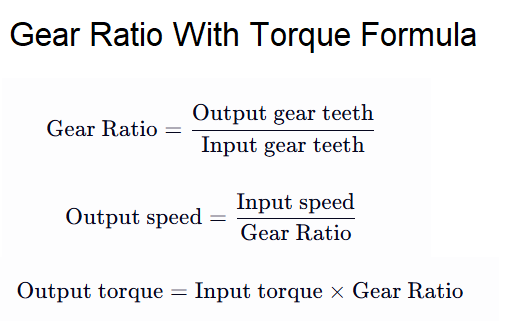

The gear ratio is the ratio of the number of teeth on the output gear (driven gear) to the number of teeth on the input gear (driving gear). It can be expressed as:

\[ \text{Gear Ratio} = \frac{\text{Number of Teeth on Output Gear}}{\text{Number of Teeth on Input Gear}} \]

If the output gear has more teeth than the input gear, the gear ratio is greater than 1.

If the output gear has fewer teeth than the input gear, the gear ratio is less than 1.

The gear ratio inversely affects the rotational speed of the output gear compared to the input gear. This relationship is given by:

\[ \text{Output Speed} = \frac{\text{Input Speed}}{\text{Gear Ratio}} \]

A higher gear ratio results in a lower output speed.

A lower gear ratio results in a higher output speed.

The gear ratio directly affects the torque of the output gear compared to the input gear. Torque is the rotational force, and its relationship with gear ratio is given by:

\[ \text{Output Torque} = \text{Input Torque} \times \text{Gear Ratio} \]

A higher gear ratio results in a higher output torque.

A lower gear ratio results in a lower output torque.

When the output gear has more teeth than the input gear:

Consider a gear system with:

Calculations:

\[ \text{Gear Ratio} = \frac{40}{20} = 2 \]

\[ \text{Output Speed} = \frac{100 \text{ RPM}}{2} = 50 \text{ RPM} \]

\[ \text{Output Torque} = 10 \times 2 = 20 \text{ N·m} \]

Results:

In an ideal system (no energy loss due to friction), the power remains constant:

\[ \text{Input Power} = \text{Output Power} \]

\[ \text{Input Torque} \times \text{Input Speed} = \text{Output Torque} \times \text{Output Speed} \]